Laser Marking Machine VS Inkjet Printer - Which One Is Better?

In today's fast-paced world, technology is advancing at an unprecedented rate. The manufacturing industry is no exception. One of the advantages of technological advancements is the ability to produce quality products that meet the increasingly sophisticated demands of customers. The production process starts with the marking of products. The two most commonly used marking techniques are inkjet printing and laser marking. Inkjet printing has been around for years, but now laser marking is gaining ground due to its advantages. Let us compare the two techniques and see why laser marking machines will replace inkjet printers in the future.

What is Laser Marking?

Laser marking is a fast, dependable and high-quality marking technique. The technology works by using a laser to etch designs or messages on a surface by melting, burning, or vaporizing the material. The resulting markings are highly precise, permanent and have a clean look.

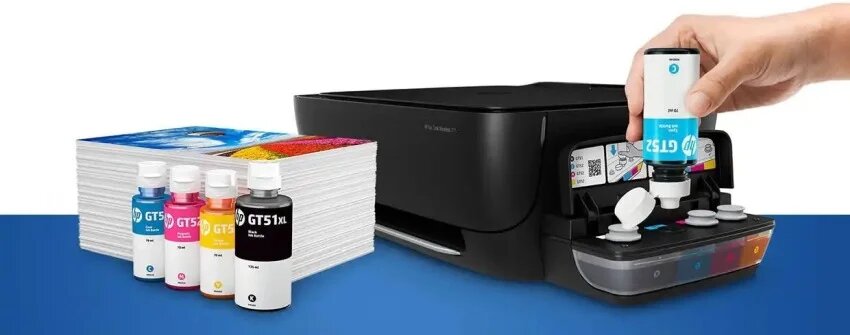

What is Inkjet Printing?

Inkjet printing uses nozzles to print liquid ink onto a material. The ink droplets form the desired design or message on the material. Inkjet printing is adaptable, and it can produce high-resolution designs with a wide range of colors.

Advantages of Laser Marking

1. Precision and Quality

Laser marking provides unique precision and superior quality of marks. The use of laser technology means that the marks are permanent and of a high quality. It is impossible to remove the marking with a solvent or alcohol, making this system suitable for products that require long-lasting marks.

2. Flexibility

Laser marking technology makes it suitable for various materials, including metals, plastics, ceramics, and glass. This technique can handle complex designs, including letters, logos, barcodes, and more.

3. No Consumables

Laser marking machines do not use any consumables, making it an eco-friendly machine. There is no ink or other hazardous chemicals involved, leaving a smaller carbon footprint.

4. Durability

Laser marking produces precise and durable marks that withstand wear and tear. The technology resists smudging, corrosion, and fading over time. This feature ensures that the marks provide optimal visibility for long periods. Therefore, it is ideal for use in harsh environments.

Advantages of Inkjet Printing

1. Color Options

Inkjet printing produces high-quality designs with a wide range of colors. The color options available to inkjet printers are not available to laser marking machines.

2. Low Cost

Inkjet printing is cheaper than laser marking machines in terms of upfront costs, making them ideal for small businesses.

3. Simple to Use

Inkjet printers are easy to use, requiring no special training. They can be installed quickly and are ready to use within minutes.

4. Speed

Inkjet printing is fast and can produce multiple copies of an image within seconds.

Conclusion

While both inkjet printers and laser marking machines have their advantages and disadvantages, laser marking machines are becoming increasingly popular in the manufacturing industry. Laser marking machines have superior precision and durability, making them the ideal choice for products that require long-lasting marks. They are also environmentally friendly and can be used on a wide range of materials. On the other hand, inkjet printing excels in producing high-resolution designs with a wide range of colors at low upfront costs. Overall, laser marking machines provide better quality and durability and will gradually replace inkjet printers, especially in the manufacturing industry.

Keywords: Hebei Naimei Bearing Group, Deep Groove Ball Bearings, Tapered Roller Bearings, Spherical Roller Bearings, Special Bearings